Need a little help figuring out MMC on some holes and whether they pass or fail. As an example, Datum A is the bottom, B and C are two sides,so i set up a coordinate system between all three. Hole is basic dimension 19.738 in one direction and the other is basic dimension 30.833, hole diameter is supposed to be.438 +.006 /.001, True Position with.007 MMC to Datums A,B,C. The hole diameter i measure is.440 and basic dimensions are 19.7409 and 30.837. I get stuck on trying to manually figure out weather it passes or not on the position.

I know we get an extra bonus tolerance but on how to calculate it is where i get stuck. Can someone help? Thanks ahead to all those that can. RE: True Position with MMC (Mechanical) 17 Aug 15 21:53. M4C7's table is correct in determining the allowable position tolerance.

But that is a diametric tolerance (presuming the given.007 was preceded by a diameter symbol in the callout).So you need to take your data of 19.7409 and 30.837 and convert the deviation in those two directions into a diagonal, using the Pythagorean Theorem:19.7409 - 19.738 =.0029 deviation in one direction30.837 - 30.833 =.004 deviation in the other direction.0029^2 +.004^2 =.00002441Then. Square root of that =.00494065 which is the radial deviationM4C7's table shows that your allowable position tolerance is a diameter of.010, which allows for a radial deviation of.005. So in a pure mathematical sense your part is within tolerance.

True Position Tolerance Calculator Excel

But I suppose we have to account for the number of significant digits and the accuracy of the measurements.Anyhow, I hope this helps you see how to convert X-Y data into the diametric shape that is usually preferred in GD&T.John-Paul BelangerCertified Sr. GD&T ProfessionalGeometric Learning Systems.

Manual Calculation Of True Position Tools Tp 2312

- True Position Calculator for Holes. Enter Position Deviation from Basic X,Y. X: Y: Add Diameter Size Over Minimum: Maximum Material Condition Adjustment.

- The basic formula for True Position is 2 x the square root of the deviation in one axis squared +. PC-DMIS/NC 2010MR3; 15 December 2010; running on 18 machine tools. This is a good 2 dimensional true position calculator. Datum(1.849 dia) need help keeps giving bad numbers checking manually.

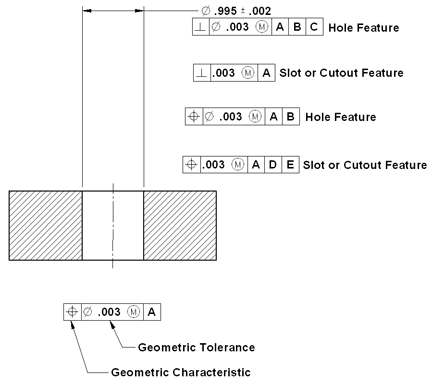

To properly position a part on the Datum Reference Frame. The desired order of precedence is obtained by entering the appropriate datum feature letter from left to right in the Feature Control Frame (FCF) (see Section 5 for explanation for FCF). The fi rst letter is the primary datum, the.